Over yrs Experience. Full Traceability on all Batches. Industry Leading Service. ISO accredited Chemical Supplier. Bespoke manufacturing to suit you. When a manufacturer enters into a formal agreement with another manufacturing firm for products or components, it is known as contract manufacturing. It is a form of outsourcing wherein the former manufacturer uses these components for his own manufacturing processes to complete his own product.

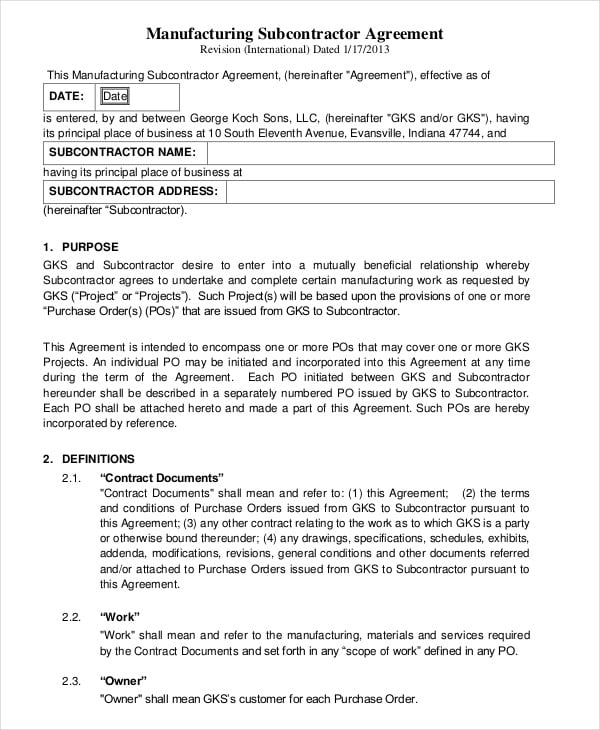

A contract manufacturing agreement usually deals with the coverage of the requirements for the manufacturing facility, the quality standards and quality measures that must be followe the terms of the manufacturing payment as well as the total amount that is needed to be paid by the client, the management of the manufacturing inventory and other elements that are necessary to be known by all parties involved. The contract does not provide for the manufacturer to provide additional services such as conversion of designs or assembly of multiple components.

The manufacturer simply makes the product for you. The Supplier can be an individual or business and is the party that "supplies," or manufactures, the goods to the Buyer. The Buyer is the party that orders the goods. The contract is designed to outline the scope of the service the manufacturer may provide to the company.

These contracts may used in several industries, such as construction or printing. A manufacturing agreement is between a manufacturer and a customer for the manufacture of goods or products. Customer” ), and Harmony Foods Corp (dba Santa Cruz Nutritionals ), a Delaware corporation (“Manufacturer” ). Organizations might sign a contract that applies to one specific product line or sign several agreements with different providers across a specific region.

The main purpose of a contract manufacturing agreement is to outline the precise terms of a relationship between two or more organizations. Commit to the delivery of excellent manufacturing services to your business clients using this contract manufacturing agreement template. Download this template on your PC or mobile device in any file format of your preference.

The document may designate the rights and obligations of each party, and include information about compensation for the service. This agreement sets out the services the manufacturer agrees to perform, standard of performance and payment of compensation and expenses. A manufacturing contract is used to state the rights and responsibilities of the parties when one company provides manufacturing services to another.

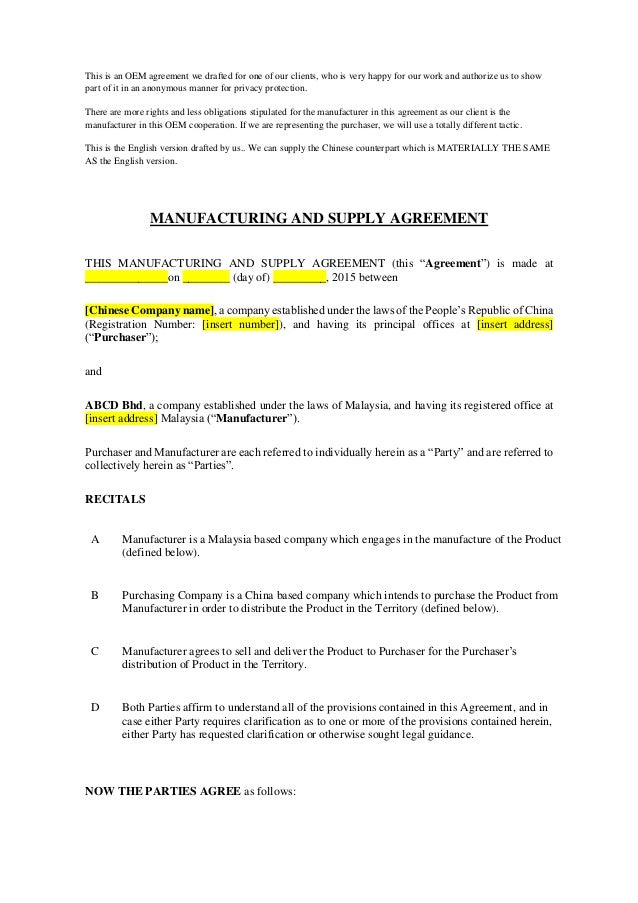

Such agreements are entered into for the manufacture of food and beverages, pharmaceuticals, industrial products, airplanes and high tech components. Common terms may cover manufacturing facility requirements, quality control, inventory management, price and payment terms, intellectual property. As covered previously, this type of agreement outlines the responsibilities of each business in dealings between a manufacturer and a distributor. Different types of companies will need these contracts.

Payments can be made as upfront payments, milestone payments or running royalties. Typically, once the agreement is in place, one party provides funds to cover initial costs.

For purposes of this guidance, we use certain terms. In a contract manufacturing business model, the hiring firm approaches the contract manufacturer with a design or formula. The contract manufacturer will quote the parts based on processes, labor, tooling, and material costs. Typically a hiring firm will request quotes from multiple CMs.

Clean, Safe, Reliable Vial Filling. An agreement for the manufacture of products that is intended for use in business-to-business transactions. The agreement sets out key obligations of the manufacturer and the customer, and includes clauses for the provision of technology and equipment, ownership of intellectual property rights, and warranty and indemnity provisions. They're used when you're hiring a manufacturer to make a product you're ready to market.

In any industry, it can be hard for small companies to establish contracts with major manufacturers. Production levels increase as the entrepreneurial team begins to move past the start up phase and into scale up.

Article Definitions 1. Manufacturing contracts are a business agreement used when making products. In addition to the design or idea, the company also provides the raw materials, or the component parts required to create the finished product.

Client wishes the Manufacturer to design, manufacture and deliver goods which the Client intends to integrate into its own final products or services, and therefore must meet certain specific requirements of the Client. A good supply agreement should include comprehensive business requirements of the buyer and the CM as well as the legal recourse that the buyer has against the CM if there is a breach.

Below are six practical tips on some of the “must-haves” in supply agreements with Chinese CMs. Make sure you contract with the right party.

Hiç yorum yok:

Yorum Gönder

Not: Yalnızca bu blogun üyesi yorum gönderebilir.